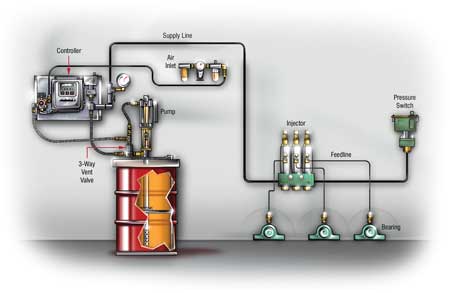

Automatic Lubrication Systems

At CA Builders, we are specialists in providing installation and repair for automatic lubrication systems. 54 Percent of bearing failures are attributed to inadequate lubrication and contamination. Additionally, too little grease, too much grease and not greasing often enough can impact bearing life significantly. With an automatic lubrication system, you can eliminate up to 50% of bearing failures.

Why Use an Automatic Lubrication System?

- Manual Lubrication typically produces inconsistent lubrication. The uneven lubrication cycle leads to wasted product and allows contaminants to enter the bearing, producing premature wear.

- Consistent lubrication (small. precise amounts applied frequently) extends bearing life and prevents unplanned downtime.

- Small, frequent amounts of lubricant while the bearing is in motion will increase bearing life.

Benefits You Can Expect From an Automatic Lubrication System

Lower Maintenance Cost

- Bearing, gear and chain life are increased by applying small, measured amounts of lubricant frequently, while the machine is operating.

- Labor for manual point- by- point lubrication is virtually eliminated- no more lock- out and tag- out and no removing guards and covers to access manual lubrication points.

- Labor for repair is reduced due to fewer bearing failures.

Increased Production

- Reduces lost production due to required machine shut down( lock –out and tag-out procedures) for manual lubrication.

Improved Safety

- Helps prevent accidents that can occur during manual lubrication.

Lower Energy Cost

- Improved lubrication for bearings, gears and chains translates to lower friction and lower energy cost.